Ask our Engineers Anything:

What makes highly-custom projects different from Commercial Off-The-Shelf (COTS) or custom componentry?

A custom-designed product can break through a crowded marketplace, and open a business to a whole new sector of consumers. When you search for a path to achieve this, however, you’ll find many options, from standard, commercial off-the-shelf (aka, COTS) components, to custom parts, to highly-custom projects. When considering creating a custom IoT application, how do you make the decision between the multitude of options?

What’s The Difference?

In a recent post, we discussed the difference between commercial off-the-shelf components, or COTS, and custom componentry. To summarize, COTS components are simply pieces that are sold direct-to-consumer with a standardized set of features. An example of this would be the Grid Connect NET485 - RS485 Ethernet Adapter, which allows a serial communications technology to connect to Ethernet, and therefore become web-enabled. However, this Ethernet adapter may not fit the physical constraints of the technology it is being integrated into, or may include superfluous firmware features. To remedy this, the adapter can also be customized to precisely match the desires of the customer.

However, the additional option of a highly-custom project also exists. This begs the question: What is the difference between custom components and a highly-custom project?

“It’s about whether or not we’re taking an existing product and customizing it, or if we’re starting from scratch and creating a brand new product,” said Adam Justice, CEO of Grid Connect.

While custom components are essentially current products modified to a customer’s specifications, those components still need to be integrated into the customer’s technology on their side. highly-custom projects, on the other hand, are the creation of a complete product, from determining the best solution to the customer’s problem at the beginning, all the way to a boxed, ready-to-sell product at the end.

Considering Highly-Custom?

Seeking out and initiating a highly-custom project is most often done when the customer wants to expand their current line of products, or modify one of their existing products to compete in a new market sector.

“These highly-custom projects are usually a new business, segment, or market for our customers to sell their products into. Because of that, there’s more investment and time involved, because the specs have to be exactly what they want,” said Rick Rockershousen, Grid Connect’s Vice President of Sales.

The process of creating a highly-custom project begins when the customer approaches Grid Connect and describes the problem they are trying to solve with their new product. While the degree of collaboration varies on a case by case basis, Grid Connect’s engineers will use ground up engineering to develop a concept based on the information gathered from these initial conversations.

“I think, in the best cases, we’re trying to understand the problem and then we’re going to go out and propose a solution,” said Justice. “We do best when the customer can trust us to figure that out.”

As part of this development process, Grid Connect performs end-customer research in addition to product development. They seek out potential purchasers of the product being developed, inquire what they would want in the product, and incorporate that feedback into the solution created.

Once all of this consumer feedback has been taken into consideration, and the client approves of the solution presented to them, Grid Connect will manage the product’s manufacturing, production, and even packaging from end to end, providing the customer with a complete, ready-to-sell item at the end of the process.

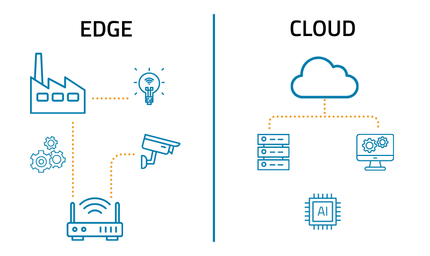

Incredibly useful and successful products have resulted from highly-custom development. For example, Grid Connect worked closely with Schlage, who specialize in manufacturing locks, to develop technology that would allow its users to manage their home locks remotely from their smart phone or watch.

Grid Connect also collaborated with Wayne Water to create their new IoT Sump Pump. The pump uses Web connectivity to provide its owner with information about the pump’s life cycle, as well as real time alerts if the pump may potentially fail due to flooding.

The Pros & The Cons

However, many companies already employ teams of engineers for development, maintenance, management, and more. Why not make projects like this in house, rather than buy something from a third party?

There are a number of reasons to consider investing in a highly-custom project even considering this. Even if a customer has a dedicated team of engineers, they may not want or be able to divert them away from critical business toward making something new. The current shortage of job-seeking engineers may certainly exacerbate this issue and further contribute to the decision to invest in a highly-custom option. This was the case for Schlage. Their engineering department needed to remain devoted to their daily business, which is their locks. Hence, Grid Connect was asked to develop a Wi-Fi adapter, enabling the connectivity Schlage desired to integrate with their locks.

On the other side of this, Wayne Water’s engineers did not have expertise in developing wireless connectivity solutions, and so they approached Grid Connect to partner in developing their connected sump pump.

“Working with Wayne Water, the relationship there is they are the pump experts. They’re in charge of everything around pumps, and explaining that to us,” said Justice. “Meanwhile, we’re the networking and hardware experts, and we’re bringing all that to the table.”

An important thing to consider when debating about buying a highly-custom project is time to market. highly-custom lead times average around six to nine months from initial consultation to finished product. Grid Connect tackles time-sensitive challenges, and can complete development on a custom IoT application in as little as three months. Even projects with longer lead times get completed faster than if the customer chose to develop internally.

“For Schlage, we delivered from project start to shipping a product in just under a year,” said Justice. “They said, ‘Wow, this is the fastest project we’ve ever shipped.”

A highly-custom application definitely requires keeping many factors in mind. However, for custom IoT applications, Grid Connect has the expertise and experience to make the process smooth, quick, and successful.

Questions To Keep In Mind:

-

Do we have access to experts who can help develop our desired product in house?

-

Can those experts be devoted wholly to product development?

-

How important to the business is total ownership of the product being sold?

- What is the desired timeframe to get the product to market?