Our Blog

Categories

- automotive

- Bluetooth

- CAN

- Company News

- custom

- ebook

- EtherNet/IP

- Events

- Internet of Things (IoT)

- modbus

- Products

- PROFIBUS/PROFINET

- Webinar

- See all

PCAN-Explorer 7: Explore the Difference

PCAN-Explorer 7 is now available, bringing major updates for engineers working with CAN, CAN FD, and CAN XL networks. This release adds support for CAN XL, expands trace analysis, and introduces modern automation for teams that monitor, analyze, transmit, and test CAN traffic using PCAN hardware.

Why Scalability Depends on Smart Connectivity Choices

A prototype that works in the lab can still collapse at scale if connectivity decisions aren’t built for growth. From device provisioning and cellular strategy to data management, power efficiency, and OTA updates, smart connectivity is what separates successful global deployments from projects stuck in pilot purgatory. The right choices early on determine whether your 10,000th device performs as reliably as your first.

Designing Reliable IoT Connectivity in Harsh Environments

Industrial IoT devices are increasingly pushed into environments where heat, vibration, moisture, chemicals, and electromagnetic noise can quickly compromise connectivity and data integrity. Designing for these conditions requires shifting the focus from basic functionality to long-term survivability, using rugged components, protected enclosures, and resilient communication strategies. When reliability matters most, understanding how and why electronics fail becomes a competitive advantage.

Beyond IoT Devkits: Proof of Concept Services for Faster IoT Prototyping

A structured proof of concept (PoC) helps teams catch technical constraints early, validate real-world performance, and avoid costly surprises later in development. By moving beyond basic devkit testing, engineers gain clearer insight into connectivity, firmware behavior, and environmental demands before committing to full production. This approach creates a faster, more reliable path from idea to scalable IoT prototype.

Industrial Networking: From Modbus to OPC UA in the Age of IIoT

Industrial networking has transformed from serial protocols like Modbus and PROFIBUS to Ethernet-based and IIoT-ready systems such as OPC UA and MQTT. As industries move toward connected, data-driven operations, interoperability, security, and scalability have become essential. Understanding how these protocols evolved reveals how modern networks enable seamless communication between devices, systems, and the cloud.

From Prototype to Scale: Connectivity Considerations at Every Stage

Scaling an IoT product isn’t just about producing more devices—it’s about designing connectivity that performs reliably as systems grow. From flexible prototyping to field validation and large-scale optimization, every design choice impacts performance, cost, and security. Building with scalability in mind ensures your network can handle volume, variability, and long-term reliability.

The Building Blocks of Connected Systems

Connected systems don’t just happen—they’re built from four essential components: sensors, gateways, protocols, and cloud platforms. Each plays a critical role, from capturing data and filtering it locally to enabling device communication and transforming raw information into actionable insights. When these building blocks are integrated seamlessly, businesses unlock greater efficiency, scalability, and entirely new connected experiences.

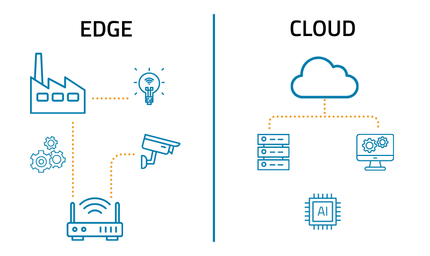

Edge vs. Cloud: Where Should Your IoT Data Live?

Choosing between edge and cloud is one of the most critical decisions in IoT system design. Edge computing delivers ultra-low latency, bandwidth savings, and local reliability, while cloud solutions provide scalability, advanced analytics, and centralized management. In most cases, the right answer is a hybrid approach that balances immediate responsiveness at the edge with the long-term intelligence and scalability of the cloud.

Get our monthly newsletter for product and technology updates